Truck Semi Trailer - the main components and how to maintain it.

3 axles dry cement tank trailer for sale

3 axles dry cement tank trailer for sale

During transportation, safety is always the first priority for truck drivers! If renting a trailer is for peace of mind, maintenance of the trailer is for life. Check everything before driving to get on the road.

Based on feedback from previous rental truck drivers and the rich experience of TITAN professionals, we have summarized here a comprehensive guide for semi-trailer use and maintenance knowledge for the majority of truck drivers:

1. Suspension system (rigid): transfer load and absorb vibration.

2. Axle and hub system: A single, two and three axle assemblies of the same structure are installed under the suspension system.

3. Landing gear lifting system: In order to make the semi trailer reliably parked after being separated from the truck, the front end of the frame is provided with two linkage or single action landing gear. It consists of a screw drive mechanism, a bevel gear drive mechanism, a two-speed reduction gearbox, a transmission rod, an operating handle, and so on.

When the handle is pushed in, the rotation can be raised and lowered at high speed, and when the handle is pulled out, the rotation can be raised and lowered at low speed. When the outriggers touch the ground, they can only be raised and lowered in low gear.

4. Traction pin: There is a traction pin connection plate connected to the tractor saddle at the lower part of the front end of the frame. The traction pin is mainly used to transmit the traction of the tractor and the braking force during braking.

The semi trailer transmits the light signal of the main vehicle to the trailer by connecting the spiral cable plug of the truck to the circuit socket at the front of the trailer.

Thus, the vehicle equip with an international general electrical system that matches the truck. The electrical system generally consists of seven core sockets, multi core cables, junction boxes, waterproof connectors, and various types of lamps and other components.

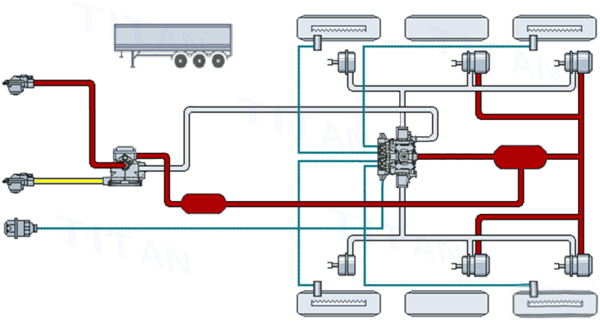

Three major parts: emergency relay valve, ABS valve, brake air chamber, most of the faults come from these three pieces.

1. Emergency relay valve: The pneumatic components of the vehicle braking system will emergency braking, shortening the brake lag time and quickly releasing the brake. Replaced the brake valve, distribution valve, acceleration valve, quick release valve in the original semi-trailer braking system.

2. ABS (Anti-lock brake system): An electronic control system that monitors and controls the speed of the vehicle during braking, including ABS solenoid valves, ABS wiring harnesses, ABS probes, ring gears and other components. Cooperate with relay valve to perform driving brake function; prevent the brake from locking, detect the wheel end speed through the probe, when the speed drops to 0, feedback the signal to the solenoid valve, the solenoid valve adjusts the air pressure, reduces the braking force and prevents the brake Lock up and increase the driving safety factor.

3. Brake chamber

It is composed of the trachea connector, inflation pipe, operating channel, gas reservoir, brake air chamber, relay valve, ABS valve, ABS sensor and wheel brake of the tractor.

The inflatable tube is connected to the tractor's gas tank through a quick pipe joint; it is connected to the tractor's brake valve through a quick joint. When the semi trailer brakes, each brake air chamber functions simultaneously.

1. Service brake: In the process of driving, service brake (foot brake) is generally used, which is convenient for decelerating and stopping during the forward process.

2. Parking brake: The parking brake is the brake used when the car is stationary. It is called parking brake, also called "hand brake". Its main function is to prevent the car from slipping forward and backward.

3. Air brake (emergency braking): The emergency braking behavior automatically performed by the trailer brake system when the inflation tube is out of air or serious air leakage, the control tube will not be broken, but the "foot brake" will fail.

Importance: When the front air pump is damaged or the inflation tube is disconnected, and the gas tank is seriously leaking, the "foot brake" of the vehicle fails or the effect is not good. The air brake is an important guarantee for the safety of the vehicle or personnel!

Vehicles need to do basic inspection and maintenance. Inspection and maintenance work can avoid unnecessary safety hazards and reduce the use cost.

3 axles sidewall semi trailer for sale

3 axles sidewall semi trailer for sale

1. Wheel maintenance

Contents of work: Disassembling the wheel hub system, cleaning the shaft head and the failed internal and external bearings, replacing the new grease with qualified grease, checking whether the bearing wear has affected the use, checking the working performance of the brake pads, brake drums, brake pads and other components, according to the results Repair and replace.

Cycle:

BPW shaft maintenance frequency: 120,000-150,000 kilometers.

VALX axis maintenance frequency: 2 years or 400,000 kilometers (1 year or 200,000 kilometers after maintenance-free).

BPW 400K / 600K: 2 years or 400,000 kilometers / 3 years or 600,000 kilometers.

Fuwa shaft maintenance frequency: 50,000-70,000 kilometers.

2. Butter

Content: Grease or apply grease to the semi-trailer legs, adjusting arms, camshafts, balance beam pins, leaf springs, etc.

Cycle:

Vehicles that are frequently used must be greased once in half a month to January or vehicles that have experienced heavy rain, and vehicles that are not commonly used need to be greased after being used again. Apply sufficient grease to ensure adequate lubrication and reduce component wear and damage caused by mechanical friction.

3 axles 40ft flatbed semi trailer for sale

3 axles 40ft flatbed semi trailer for sale

Container repair method:

(1) Patch repair: for holes, cracks, etc.

(2) Replacement maintenance: for large area damage, severe deformation.

(3) Scraping putty paint repair: It is aimed at small deformation and no damage.

(4) Adhesive repair: For cracking, common composite plate boxes are common.

(5) Liner welding: cracking and welding.

(6) Sheet metal correction: for deformation and bending, such as hinges, locks, etc.

(7) Glue and seal: rain or water leakage from the top or side panels.

(8) Reinforcement of steel: for the overall deformation of the composite board, box expansion, etc.

Welcome to click “Resource“, you can get more article about our trailers.

Click “Product“, you can find your favorite semi trailer.

And welcome to leave your question in the message box below, thanks!