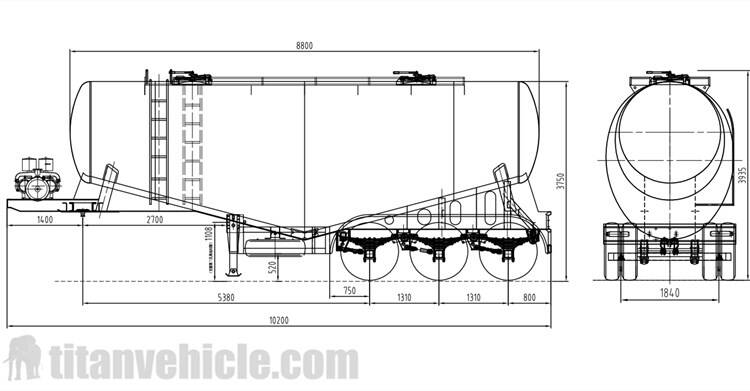

35cbm 3 Axle Bulk Cement Trailer will be sent to Nigeria

The customer from Nigeria first contacted us through facebook, it is the first time the customer bought the 35cbm 3 axle bulk bulk cement trailer from TIAN VEHICLE. We sent many pics, videos and drawings of the bulk cement cement trailers, and the customer was deeply attracted by the bulk cement trailer from TITAN's various detailed services. The trailer is customized, we finished the bulk cement trailer according to the drawing the customer provided. As was expected, the customer is satisfied with the bulk cement trailer.

The following is the completed bulk cement trailer. TITAN professional technicians have tested it to ensure the quality of semi trailers. After the test is completed, it will be sent to Nigeria immediately.

The pressure of the tank body of a bulk cement trailer is generally controlled by man. Explosion accidents are mostly caused by improper operation.

Here, we solemnly remind that operators of bul cement trailers should pay attention to the following points:

1. Bulk cement trailers are prone to excessive pressure during the entire discharge operation, which can be divided into three situations: the discharge valve in the pressurization stage before discharge is opened late, resulting in excessive pressure; early discharge due to air supply greater than The discharge volume of the tank body is easy to cause excessive pressure; the pipeline blockage during the discharge process is easy to cause excessive pressure

2. If you need to open the lid of the bulk cement trailers, you must ensure that there is no pressure difference between the inside and outside of the tank (observe the pressure gauge pointer is "0") to operate. When the negative pressure is in the tank, the cover cannot be opened due to huge pressure, and it is more dangerous when it is overpressure (positive pressure). If it is opened rashly, it may be accidentally killed by flying.

3. During loading and unloading operations, the operator needs to monitor the pressure and discharge conditions in the tank at all times, and must ensure that the air compressor is in good working condition. During the ash discharging process, the state of the pressure gauge and the pressure relief valve must be kept in mind!

If it is found that the pressure in the tank exceeds the specified pressure, pressure reduction measures shall be taken immediately. Many drivers like to sleep at this time or leave the scene, which is very dangerous. During the loading and unloading process, if there are abnormalities in the air compressor or pipeline valves, emergency stop measures should be taken immediately to stop the work to ensure foolproof.

1. Tank structure of the bulk cement trailer: The tank body is made of high-strength alloy steel from a well-known domestic steel plant, which has good performance and reliable welding; the tank body adopts advanced technology to ensure high strength and good airtightness of the tank body; it adopts a throat fluidized bed , Non-side slide structure, gas and material separation device and safe discharge device, effectively reduce the weight of the vehicle and increase the discharge speed.

2. Power device: The power system can choose the power of the main vehicle, which saves costs and is easy to operate; it can also be equipped with a traditional diesel engine transmission; it can also be driven by a motor to reduce fuel consumption, effectively saving costs for customers, and multiple options to maximize It is convenient for customers to choose a source of power.

3. Use cast aluminum lightweight material cover: the top cover can be easily lifted with one finger, the fasteners are all galvanized, and the unique design of the material port eliminates the accumulation of materials, which greatly facilitates customer use and reduces maintenance cost.

4. Use of lightweight materials: aluminum alloy accessories are widely used, such as: aluminum alloy legs, side guards, rear guards, mudguards, outer escalators, integrated detachable anti-skid walking platform, discharge butterfly valve, etc., light structure and operation It is more flexible and convenient, wear-resistant and has a long service life, high-end beauty and safety, while ensuring performance, it has strong corrosion resistance, preventing rust and reducing customer maintenance costs.

5. Braking system of the bulk cement trailers: Double pipeline braking system is adopted, equipped with imported relay valve, pneumatic main vehicle braking system and ABS anti-lock braking system to ensure the safe driving of the vehicle.

6. Suspension system: The high-strength, light-wearing suspension of a well-known domestic brand is adopted. It is composed of tandem light-weight leaf springs, high-strength tie rods and supports to ensure the load balance of each axle and effectively prevent the phenomenon of vehicle deviation and tire gnawing.

7. Traveling mechanism: The axle adopts Fuhua and other well-known domestic brands, uses aluminum alloy steel rims and tubeless tires, and is reasonably matched to adapt to various road conditions to ensure stable, safe and reliable driving.

8. Paint spraying: The tank body has undergone multiple processes such as shot blasting, sanding, cleaning, primer, middle coating, top coat, and drying, which effectively improves paint film adhesion. The salt spray test proves that the tank body has strong corrosion resistance.

Through the video, you can learn more different types of the 35cbm bulk cement trailer , 3 axle cement ttrailer , bulk cement truck trailer, as well as the packaging process, testing and feedback.