Windmill Blade Adapter will be sent to Vietnam

This is a Wind Blade Adaptor purchased by a Vietnamese customer. Because the customer has a base for the wind blade adaptor, the customer only purchased the wind blade adaptor. The sales manager and Jacky discussed it on WeChat for a long time. The customer chose us because the quality of TITAN is better than other manufacturers. Many local customers are using TITAN semi trailer. In addition, the wind blade adaptor requested by the customer can be customized in TITAN. Below is the picture of the shipment.

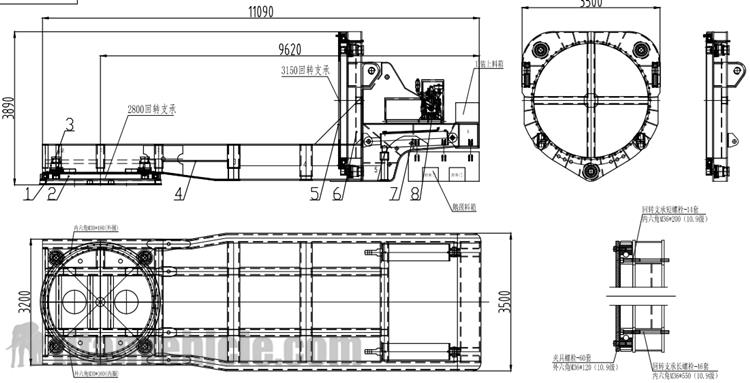

The large turning angle of the ant is 45°, the cargo platform is a modular cargo platform, and the cargo platform can be combined longitudinally; the wind blade adaptor a dual-pipe air-cut brake system, and is equipped with a hand brake device, which can be parked independently by a supporting device.

Windmill blade adapter

In this design structure, the turbine blades are fixed on the adapter. The special thing about this windmill blade adapter trailer is that the adapter is customized for the blade. This means that it is unlikely to be used for other functions. If you only need to transport wind turbine blades, then it is the trailer you need. Although it is usually made of the best materials with sufficient yield strength, its customized blade design may not make it suitable for other types of loads.

Advantage:

These type of trailers are used to transport turbine blades on mountain roads and curved roads as well. Because of the fact that extendable trailers are too long, when it comes to a mountain road, it is hard to steer hence the need for the special blade trailer. The design is made in such a way that the blade adaptor can lift up and down making it easier for the trailer to steer easily.

The blade shape of the wind turbine blade is designed according to the aerodynamic characteristics, and the thickness of the trailing edge of the blade is small; the bucket structure adopts the shell and double beam design type, and the blade well shell is thin. According to the characteristics of the shape and structure of the blade, the stability, reliability and safety of the blade structure should be ensured during transportation, hoisting and storage.

During transportation, each blade needs at least two support points, one at the root of the blade, and the other at about 2/3 of the length of the blade (pitch) or the length of the blade body (fixed blade), so that it can be divided equally. Deflection.

When supporting the main body of the blade, in order to evenly bear the load, it is necessary to use a support pad that is basically the same as the local wing shape. The radial length of the supporting pad is at least 500mm, the chord width is at least 500mm, and the thickness of the felt layer between the blade and the pad is at least 5mm.

The blade root support is supported at a position 100mm from the blade bow to the blue plate, At least 4 bolts are required for fixing. The transport bracket should be firmly fixed to the carrier body, and no relative movement should occur during transport. The elongation from the main support of the blade is not allowed to exceed 1/3 of the length of the blade. When encountering special road conditions, the extension length of the blade tip can be temporarily extended appropriately, and it should be restored immediately when the conditions are met.

When the blade is transported, the blade is not allowed to be placed horizontally, that is, the chord line at the maximum chord length of the blade is not allowed to be parallel to the ground, otherwise the blade strength should be affected

Video of the windmill blade adapter